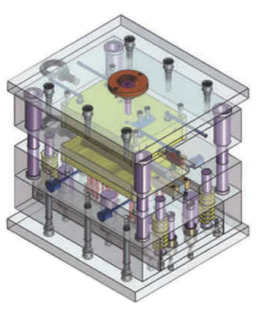

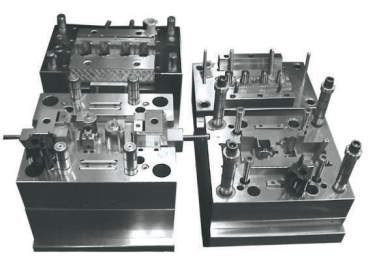

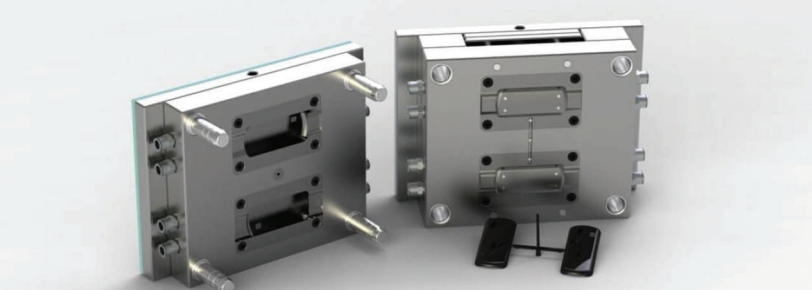

IDEPRO Engineering Asia Pvt.Limited is a Denmark based industry leader in manufacturing plastic injection mold systems and is equipped with a variety of techniques to produce prototypes from plastics, light metals, and EPS. IDEPRO’s technical accuracy demanded a high quality output on mold design. SolidWorks Add-in developed by Trikonic has helped achieve the product output with great quality.