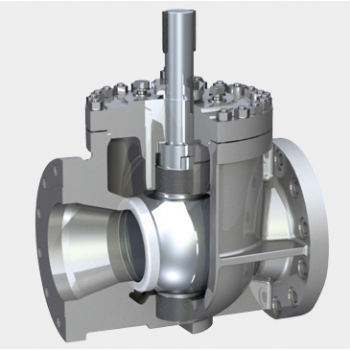

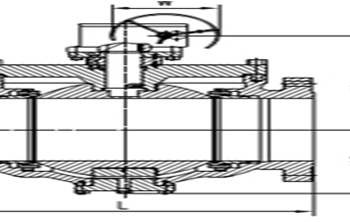

Worldwide Oilfield Machine (WOM) is a globally recognized, multinational company and world leader in manufacturing Valves for Oil and Gas Industry. WOM wanted to eliminate the technical errors in valve design and reduce time spent on engineering and design for Top Entry Ball Valves by implementing design automation for designing the valves.