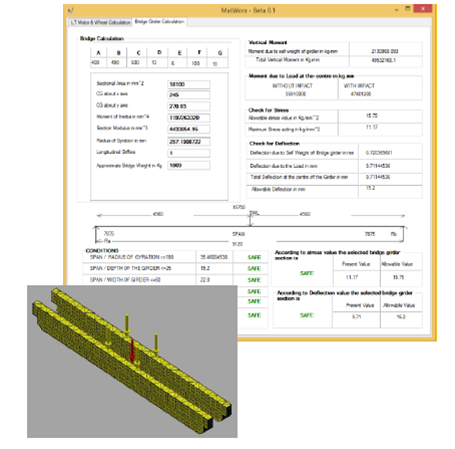

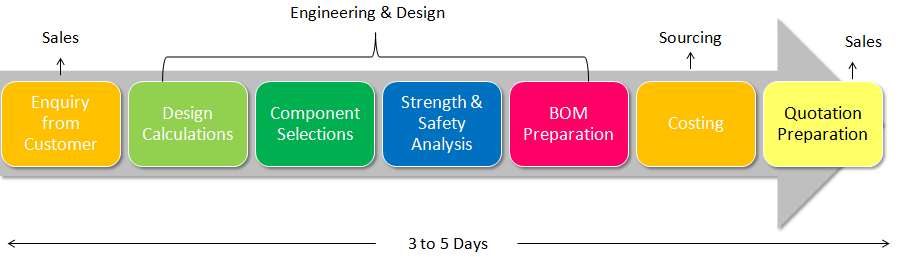

Crane manufacturing is having many complex engineering calculations for qualifying it’s design standards. These engineering calculations are applied to component selection and steel sheet size selection for the required crane design. Our Design Automation Solution helped the customer to improve the sales turn around time.